In modern home decoration, the choice of floor is critical. LVT floor (vinyl floor) and laminate floor are two mainstream floor materials that have their own distinct characteristics. This article will analyze the similarities and differences between these two types of floors in detail to help you make a wise choice.

1. Common features: Why are they so popular

LVT flooring and laminate flooring have become mainstream in the market mainly due to the following common advantages:

a. Excellent Wear Resistance:

Both surfaces are specially treated. LVT flooring uses UV coating, and laminate flooring uses aluminum oxide coating; both have excellent scratch and wear resistance, and can withstand the test of daily use.

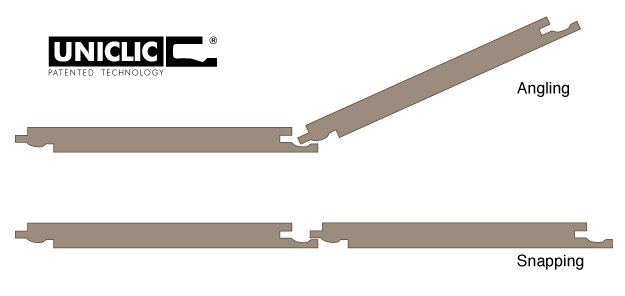

b. Convenient Installation Method

Both adopt a suspended lock installation design; no glue is needed, the construction is simple and quick, making it especially suitable for DIY enthusiasts to install by themselves, which greatly saves on decoration time and cost.

C. Wide range of application scenarios

Whether it is the living room and bedroom in the home space, or the office and shop in the commercial space, these two types of flooring can perfectly adapt to meet the needs of different environments.

D. Affordable price

Compared to solid wood flooring, both products offer higher cost-effectiveness and are ideal choices for individuals with limited budgets.

2. Differences of LVT & Laminate Flooring

Although similar in appearance, LVT flooring and laminate flooring have significant differences in material structure and performance.

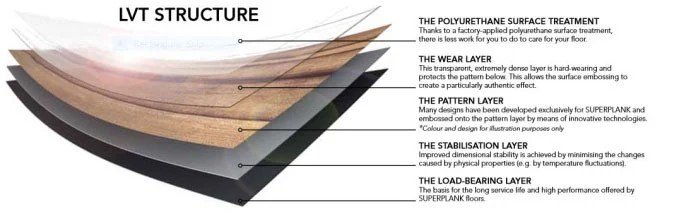

a. Comparison of materials and structures

The LVT floor is made of polyvinyl chloride (PVC) as the base material and has a multi-layer composite structure: the top layer is the wear-resistant layer, the middle layer is the high-definition printing layer, the bottom layer is the PVC elastic layer, and the bottommost layer usually comes with cork or IXPE noise-reducing pads. This unique structure endows the LVT floor with excellent elasticity and waterproof properties.

The laminate flooring is made with high-density fiberboard (HDF) as the base material. It is formed by pressing wood chips under high temperature and high pressure. Its structure consists of a wear-resistant layer on the surface, a decorative paper layer, an HDF base material layer, and a balance layer at the bottom. This structure gives it high hardness, but it has no waterproof property at all.

Key difference: The core advantage of LVT flooring lies in its complete waterproofing and elastic foot feel, while laminate flooring focuses more on hardness and impact resistance.

b. Performance characteristics

1) Waterproof performance:

LVT flooring is completely waterproof and can be laid without any concerns in damp areas such as kitchens and bathrooms. Even after prolonged contact with water, it will not deform. Laminate flooring, however, will rapidly expand and deform when exposed to water and is only suitable for dry environments.

2) Foot feel experience

Due to the elastic property of PVC material, LVT flooring offers a soft and comfortable stepping sensation, providing an excellent barefoot walking experience. It also has a certain sound insulation effect. On the other hand, laminate flooring is harder and has a more rigid stepping sensation, with relatively poorer sound insulation performance.

3) Wear Resistance Grade

Structurally speaking, the wear-resistant layer of laminate flooring is aluminum oxide, while that of LVT flooring is transparent PVC, and its surface has been treated with PU. Its wear resistance is far superior to that of laminate flooring.

Similarly, it can be seen from the national standard regulations that the wear resistance of ordinary laminate flooring is 4,000 to 6,000 revolutions, and even for commercial-grade flooring, it is only 9,000 revolutions.

The wear resistance of LVT flooring can reach over 30,000 revolutions. It is not only suitable for household use, but also for commercial and industrial environments, featuring extremely strong wear resistance.

In conclusion, both have good wear resistance, but LVT flooring usually reaches the AC4-AC6 wear resistance level, while laminate flooring is mostly at the AC3-AC5 level. However, laminate flooring performs better in terms of impact resistance and pressure resistance.

4) Environmental performance

LVT flooring contains no formaldehyde, but some products may contain plasticizers such as phthalates (it is recommended to choose products without phthalates). The environmental friendliness of laminate flooring depends on the quality of the glue. Low-end products may have the problem of higher formaldehyde emissions (it is recommended to choose ENF grade or F4 star products).

5) Temperature adaptability

LVT flooring has excellent resistance to both cold and heat, making it highly suitable for floor heating environments. Although laminate flooring can also be used for underfloor heating, high temperatures may accelerate the release of formaldehyde (a dedicated underfloor heating model should be chosen).

c. Appearance

1) Texture simulation degree

LVT flooring adopts high-definition printing technology, which can highly reproduce the natural material textures such as wood grain and stone grain, and the touch is also relatively close to the real material. The decorative layer of laminate flooring is made of ordinary printed paper, which has a slightly stiff texture and lacks a realistic touch.

2) Seam treatment

High-end LVT flooring can achieve seamless splicing, presenting a more overall and unified visual effect. Laminate flooring always has obvious seams, which, to some extent, affect its aesthetic appeal.

d. Service life and cost performance

Under normal usage conditions, the service life of LVT flooring can reach 15 to 25 years. Its waterproof property makes it perform particularly well in damp environments. The lifespan of laminate flooring is approximately 10 to 20 years, but it will significantly shorten its service life when exposed to water.

In terms of price, LVT flooring is of medium price, while laminate flooring is even cheaper. However, in terms of long-term cost performance, LVT has a significant durability advantage in humid areas.

3. Environmental Protection Considerations

a. Environmental friendliness in the production stage

The main raw material of LVT flooring is PVC. The production process has relatively high energy consumption and may use plasticizers (choosing products free of phthalates is more environmentally friendly). However, it does not use wood at all, which helps to reduce the consumption of forest resources.

The base material, HDF of laminate flooring, consumes a large amount of wood, and the adhesive used in the manufacturing process can cause formaldehyde release problems. High-quality products that use eco-friendly adhesives (such as MDI adhesives) can effectively reduce pollution.

b. Environmental performance during the usage stage

LVT flooring has no risk of formaldehyde release, but some low-quality products may release volatile plasticizers at high temperatures. The environmental friendliness of laminate flooring is entirely determined by the formaldehyde emission grade (ENF grade is the best), and inferior products may release harmful gases for a long time.

c. Waste disposal and recycling

The PVC material used in LVT flooring is theoretically recyclable, but the actual recycling system is still not perfect. Most of them are landfilled or incinerated (it should be noted that incineration may produce harmful substances such as dioxins). The HDF base material of laminate flooring is difficult to recycle. It is usually crushed and used for low-end building materials or incinerated. The aldehyde glue contained in it will aggravate environmental pollution.

Suggestions for environmental protection improvement:

- Choose LVT flooring made of recyclable PVC (some leading brands have launched recycling programs)

- For laminate flooring, FSC-certified wood and eco-friendly glue products are preferred

4. Purchasing Guide: Make the best choice based on your needs

Situations suitable for choosing LVT flooring

- Places that require waterproof performance (such as kitchens and bathrooms)

- A space that pursues a comfortable foot feel

- A decoration style that emphasizes the authenticity of textures

- The laying requirements for the floor heating environment

Situations suitable for choosing laminate flooring

- The decoration budget is relatively limited.

- Dry areas (living room, bedroom)

- Occasions that require high impact resistance

Suggestions for prioritizing environmental protection

- LVT flooring: Choose products marked with the “Phthalate-free” certification

- Laminate flooring: Choose ENF grade (formaldehyde ≤0.025mg/m³) or F4 star standard

Conclusion

LVT flooring and laminate flooring each have their advantages and are suitable for different decoration needs and scenarios. LVT flooring stands out in terms of water resistance, comfort, and environmental friendliness, making it particularly suitable for damp areas and consumers who pursue quality. Laminate flooring is known for its high cost-performance and impact resistance, making it an economical choice for dry areas. It is suggested that consumers make the most suitable choice for themselves by weighing various factors based on the actual space characteristics, usage needs, and budget situation. No matter which type of flooring you choose, it is recommended to give priority to its environmental performance to create a healthy and safe living environment for your family.